« Handheld: Pursuit of a vision | Main | Rugged notebooks: challenges and opportunities »

May 17, 2013

How Motorola Solutions made two mobile computers condensation- and freezer-proof

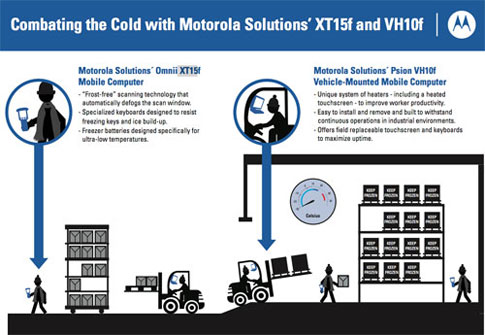

Good phone conversation today with the PR folks from Motorola Solutions. The occasion was the introduction of two interesting new products, the Omni XT15f industrial handheld, and the Psion VH10f vehicle-mount computer. The key here is the "f" in both of the names. It stands for "freezer" and that's what the two new devices are all about. Big deal?

Actually, yes. At least for workers who use their computers in and around freezers. That includes storage of perishable foods, the strictly temperature-controlled environments where medications are stored, and numerous other places for goods that need to be or stay frozen. So what's the issue? You just get devices that can handle the cold and that's it, right?

Yes, and no. While the environmental specs of most rugged computing devices include their operating temperature range, the range only tells the temperatures within which the device can be used. In the real world, and particularly when working around freezers, temperature alone isn't the whole issue. What matters is how a device can handle frequent, rapid changes in temperature. The real enemy then becomes condensation, and not so much temperature. Extreme temperatures remain an issue, of course, but one that must be addressed as part of the larger issue of rapidly changing temperatures.

So what exactly happens? Well, if you go from a hot and humid loading dock into a freezer, the rapidly cooling air in and around a device loses its ability to carry moisture, which then becomes condensation. That condensation then freezes, which can cause frost on displays, rendering them illegible, frozen keys on the keypad, and possibly internal shorts. When the worker leaves the freezer environment, the frost quickly melts, again affecting legibility of the display and possibly causing electrical shorts. It's quite obvious that extended cycling between those two environments not only makes the device difficult to use, but it's almost certainly going to cause damage over time.

Now add to that the slowing down of displays in extreme cold and the general loss of battery capacity, and it becomes obvious why this is an issue for anyone using mobile computers in those environments. And hence the new "freezer" versions of those two Motorola Solutions products (Omnii XT15f on the left, Psion VH10f on the right).

So what did Motorola do? Weber Shandwick's ever helpful Anne Norburg suggested I talk to the source and arranged the call, and so I had a chance to ask Amanda Honig, who is the Product and Solutions Marketing Manager for Enterprise Mobile Computing, and Bill Abelson of Motorola's media team. The overall challenge, they said, was to provide reliable "frost- and condensation-free" scanning. In order to do that, they had to address a number of issues:

Since the scan window can fog up, they used internal heaters to automatically defog the window, thus facilitating accurate scans under any condition.

Since external condensation can quickly freeze around keys and make the keypad difficult or impossible to operate, they designed special freeze-resistant keyboard layouts with larger and more widely spaces keys.

Since the airspace between the LCD display and the touchscreen overlay can fog up from condensation and make the display unreadable and imprecise to operate, they optically bonded layers to eliminate air spaces and used a heater to eliminate internal display fogging.

Since the airspace between the LCD display and the touchscreen overlay can fog up from condensation and make the display unreadable and imprecise to operate, they optically bonded layers to eliminate air spaces and used a heater to eliminate internal display fogging.

Since battery capacity tanks in very low temperatures and standard batteries can get damaged, they used special low temperature batteries with higher capacities and minimized performance loss at low temperatures.

And to make sure this all worked transparently and without needing any worker involvement, they included environmental sensors and heater logic circuitry so that the device automatically handles the rapidly changing temperatures and humidity. There are, however, also ways to do it manually.

Finally, since it makes no sense to overbuild, they offer two versions. One is called "Chiller" and is considered "condensation-resistant," with an operating temperature range of -4 to 122 degrees Fahrenheit. The other is called "Arctic" and is considered "condensation-free." That one can handle -22 to 122 degrees. The Chiller and Arctic versions add US$700 and US$1,100, respectively, to the cost of the basic Omni XT15 handheld computer. If it means fewer equipment hassles when getting in and out of freezers, that's a small price to pay.

There's another interesting aspect to all this. Changing and upgrading existing equipment is never easy, but in this case it was made easier because Psion, even prior to its acquisition by Motorola Solutions, had given much thought to modular design as a means to quickly and easily adapt to special requirements, easier maintenance, and also to future-proofing. At the very least this means much of the repairs and maintenance can be done in the field. And I wouldn't be surprised if it also made it easier to come up with these special versions

Posted by conradb212 at May 17, 2013 11:19 PM