|

|

Enterprise Mobility and Explosion Protection:

Keep Your Eyes Open When Shopping for Hardware!

With the ongoing quest for cost-effective productivity enhancing measures, there's an increase in demand for intrinsically safe mobile computing gear, the safe operation of which requires far more than mere certification documentation. Improper deployment can have life-threatening consequences, and ultimately the responsibility for proper use is with the user.

by Johannes Buhn, Director BARTEC Safe.t Academy, translated from German into English by Conrad H. Blickenstorfer, Ph.D.

Anyone familiar with the field of explosion protection knows that based on their very functionality, electronic devices must be viewed as potential sources of ignition. Anyone familiar with the field of explosion protection knows that based on their very functionality, electronic devices must be viewed as potential sources of ignition.

For that reason such electronic devices can only be used in Ex areas — areas where explosive atmospheres are, or may at some point be, present — if they are equipped with appropriate additional ignition protection measures.

Anyone operating electronic devices in EX areas is mandated by law to guarantee the safety of co-workers in those areas and to organize safety precautions accordingly, from product selection to implementation and to actual use.

For mobile devices, specifically, this means that decision makers at the point of procurement must significantly broaden section criteria for such equipment compared to the purchase of standard mobile electronic devices that do not specifically provide explosion protection.

Observing Ex Protection Specifics

The reason why examination of technical specifications such as processor performance or available operating systems is insufficient for vendor selection lies in the various regulations covering Ex areas (RL 19999/92/EG and RL 2014/34/EU).

The reason why examination of technical specifications such as processor performance or available operating systems is insufficient for vendor selection lies in the various regulations covering Ex areas (RL 19999/92/EG and RL 2014/34/EU).

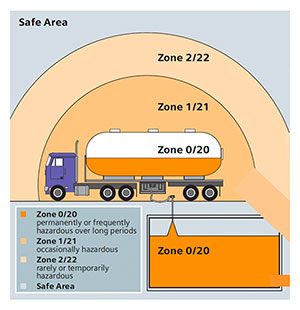

Apart from general safety requirements, permissible use also means keeping staff from bringing their mobile electronic aids into hazardous location zones with higher explosion protection requirements.

Effective enforcement of such restrictions isn't always easy. Which places even greater importance on the comparison of Explosion Protection features prior to procurement, and matching the selection of mobile electronic devices according to the explosion protection requirements of the most restrictive intended deployment zone.

For example, mobile devices certified for product category 2G/2D are suitable for deployment in Zone 1/21, but may also be used in Zone 2/22, thus facilitating seamless use in the entire intended Ex area. This also applies to explosion protection sub categories and temperature classification in gasses and fumes, as well as for maximum surface temperatures and explosion sub classifications for dusts.

The table to the right presents a list of relevant Ex parameters (device election criteria) and a presentation of the interrelations, EN 60079-14.

Prerequisites for Safe Operation

In addition to meeting the above initial requirements, in keeping with the intent of RL 1999/92/EG, European operators must guarantee the required safety levels throughout the entire product life span — including maintenance, service and repair.

If, for example, the battery compartment cover of an ATEX-certified mobile device no longer locks reliably due to a drop, the device must not simply be "repaired" with a piece of tape. Such a quick fix would defeat the intended and certified ignition protection precautions for use in Ex zones, and thus represent gross negligence with potentially life-threatening consequences.

Unfortunately, many decision makers are not aware that the responsibility for safe operation does not solely rest with the manufacturer.

According to the 2014/34/EU directive, the manufacturer is required to engage a qualified third party to test and certify both electronic devices and production processes for targeted product categories (categories 1 and 2), appropriately mark same, and include relevant cautions for safe operation in supplied operating manuals.

The responsibility for observation, application and testing of safety measures, however, lies with appropriately trained and skilled personnel on the operator's side.

What Does "Intrinsically Safe" Mean?

In addition to listing pertaining Ex certificates, such as 2014/34/EU compliant examination certificates, suppliers often advertise their products to be "intrinsically safe." In essence, the term intrinsic safety suggests ignition protection that's inherent to the product design itself. In mobile devices this refers to electric circuits whose voltage and current never exceed levels where they might ignite potentially explosive atmospheres. Temperatures never exceed allowable levels, nor can interruption or short circuits lead to sparking sufficient to cause ignition.

Combining Intrinsic Safety and Optimal Usefulness

Per definition, the terms "intrinsically safe" requires that devices carrying such designation have expertly been rendered intrinsically safe. Per definition, the terms "intrinsically safe" requires that devices carrying such designation have expertly been rendered intrinsically safe.

Ideally, this reflects not only the current state of safety technology in accordance with pertaining technical norms and guidelines, but also affords customers the desired gains in efficiency and productivity, and operators optimal use and convenience.

This is what sets innovative suppliers of Ex-certified mobile devices apart. Optimal intrinsic safety design facilitates appropriate device functionality for safe use in Ex zones.

Examples are application-optimized I/O and wireless communication in field devices or machine running and operation. Intrinsically safe modules such as USB keys, scan engines and cameras enhance the value of mobile devices for mobile work and communication in Zone 1/21 operations.

Task-optimized devices further benefit from value-added details that simplify and enhance use, such as extended operation via exchanging batteries directly in Ex zones.

Avoiding Costly Mistakes

Users of mobile devices in EX zones seeking to avoid unnecessary risks and costly mistakes in procuring and implementing enterprise mobility are served well observing the following recommendations in the selection of solutions providers.

- Determine whether the vendor has a name and reputation in the manufacturing of Ex technologies. Explosion protection further requires a high degree of vendor know-how in safety technologies as well as comprehensive after-sale service and support.

- Look for length of pertaining company experience, a global references portfolio, and internationally recognized testing certificates (ATEX, IECEx, UL, FM) based on current EN, IEC and NEC standards as indicators of experience and expertise.

- Also helpful is the availability of expert support in setting up application-specific communications interfacing and software installation as well as ongoing relevant training offerings.

- Finally, the presence of global service is essential for timely maintenance and repair.

IT personnel unfamiliar with the specifics of Ex zone operations are advised to procure the services of an experienced Ex protection expert who will not only be able to pinpoint issues and suggest solutions, but is also knowledgeable of all pertaining safety requirements and regulations. Because, after all, it's not just about device performance and properties for optimal gains in productivity, but also doing everything possible to protect human lives, assets, and the environment.

Sources and references:

DIN EN 60079-0; VDE 0170-1:2014-06

Explosive atmospheres - Part 0: Equipment - General requirements

DIN EN 60079-11; VDE 0170-7:2012-06

Explosive atmospheres - Part 11: Equipment protection by intrinsic safety

DIN EN 60079-14; VDE 0165-1:2014-10

Explosive atmospheres - Part 14: Electrical installations design, selection and erection

Directive 2014/34/EU of the European Parliament and of the Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres (recast) Text with EEA relevance.

Directive 1999/92/EG of the European Parliament and of the Council of 16 December 1999 on minimum requirements for employee health and safety improvements related threats from potentially explosive atmosphere.

For more info, see BARTEC Enterprise Mobility

|